Decker process engineering

Ion exchanger system

Regenerate ion exchangers

Regenerate ion exchangers

Maintenance and service of ion exchanger system,

waste water system

Produce demineralized water:

Demineralization cartridge,

demineralization system

Ion exchanger system and reverse osmosis system

Approvals & training

WHG, Chemicals and AwSV

Regeneration of ion exchanger system and ion exchanger: COMPLETE WATER MANAGEMENT

Vom Wasserhahn, der Herstellung von VE Wasser, bis zum letzten Schritt der Abwasserbehandlung, Ionenaustauscheranlage, Umkehrosmoseanlage Industrie Selektivaustauscher sowie extern Ionenaustauscher regnerieren

Ion exchanger plant, demineralization plant, demineralization cartridge, reverse osmosis plant industry, electrodeionization for ultrapure water production, chemical physical waste water plant, selective exchanger plant, ion exchanger and ion exchanger regeneration, i.e. the external regeneration of ion exchange resin (such as mixed bed resin regeneration and / or ion exchange cartridges regeneration, also from ultrapure water production) in the ultrapure water industry.i.e. the external regeneration of ion exchanger resin (e.g. mixed bed resin regeneration and / or ion exchanger cartridge regeneration, also from ultrapure water production) in the D-A-CH region, the EU and worldwide.

Our products

Our service

Environmental protection and conservation

Our mission is

the long-term preservation

of resources

Our mission is the long-term preservation of resources. At Decker Verfahrenstechnik, we think sustainably. By separating material flows at our customers, e.g. via an ion exchanger system for the external regeneration of ion exchangers (cartridges), we are able to generate a new value chain. This begins with the use of the resource by our customers and ends with it again. Despite innovative technologies, such as industrial reverse osmosis systems with EDI and polisher ion exchangers (e.g. from Lanxess Lewatit or Purolite), we consolidate resource losses via an ion exchanger system in the cycle or in an industrial chemical-physical wastewater system via a selective exchanger system and reunite them in a synergetic process as part of the ion exchanger regeneration service to form the original resource, which is then available to the customer again. Thanks to our own PV system, we are able to map the process in a largely energy-optimized manner. Through all of our technologies, we ensure the preservation of resources for the development of future generations, as set out as a goal in SDG 6, 6.3 and 6.4 of the United Nations and the German National Water Strategy II.4. Thanks to our own PV system, we are able to map the process in a largely energy-optimized manner. Through all of our technologies, we ensure the preservation of resources for the development of future generations, as set out as a goal in SDG 6, 6.3 and 6.4 of the United Nations and the German National Water Strategy II.4.

About Decker Verfahrenstechnik GmbH

Industrial

Environmental company

for water treatment

since 1987

The company’s history goes back to the foundation of the “Eisengießerei Nürnberg-Mögeldorf Gebrüder Decker” in 1891, which developed into Gebrüder Decker KG.

In 1987, Gebrüder DECKER Verfahrenstechnik GmbH was entered in the Nuremberg commercial register as an independent company in the field of technical environmental protection. In 2014, the company was renamed Decker Verfahrenstechnik GmbH.

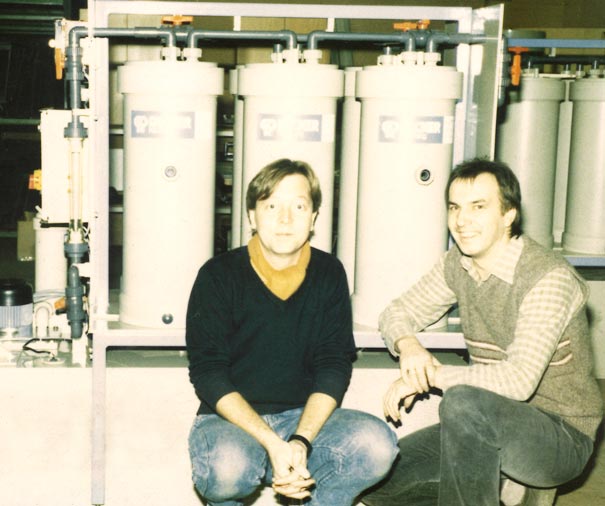

Reinhard Naujoks

and Erwin Fischer

now and

in 1987